ATLAS e-News

23 February 2011

News from the Pit

18 February 2008

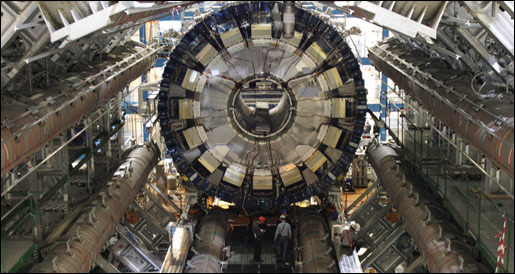

The tile calorimeter early in the installation work

Last week the Small Wheels were attached to the ATLAS detector, marking the beginning of the final stages of installation work. But elsewhere in the detector, refurbishment of some of the earliest installed components is nearing completion.

Irakli Minashvili is in charge of installing the front electronics of the tile calorimeter. "Before the detector is closed this spring, we have some refurbishments to do - installing some new components to replace old ones," he says. "Then the new components need testing, so we are also putting in place commissioning."

"There are in total around 10,000 electronic channels," Irakli says. "That doesn't sound like many, but for a calorimeter that's a big amount. More than half of those channels are now being refurbished and tested."

The tile calorimeter needs specially designed electronic components, Irakli explains. "The calorimeter is detecting an analogue signal, not just a simple digital 'yes' or 'no'," he says. "And we also need to measure the charge of a signal. That requires very specific electronic components."

But many of those electronic components failed during commissioning work last year, says Irakli. "It's always difficult making components for something on this scale," he says. "The design and concept was good, but a problem emerged during testing. Of course, we're lucky to have identified that before we closed the calorimeter!" he jokes, before adding that one purpose of commissioning exercises is to identify such problems.

But Irakli is optimistic that the new channels will perform better than those they are replacing. "The first refurbishments were done more than eight months ago, and the electronic components we installed then are still working well. So the new electronics should work well too," he says.

Elsewhere, Luis Hervas and the LAr team are facing a similar challenge. Over the last two years, the team was installing 1600 electronic boards onto the 58 crates on the cryostats. “We had just about finished installing them all when we found a design flaw that could have had an impact on the boards after several years of use,” says Luis.

It wasn’t necessary to fix the problem immediately, but because the schedule permitted, they decided to take advantage of that time to make their repairs. “The fix was very simple,” says Luis. “All we had to do was solder two extra resistors to each board.” But removing the boards was challenging. “Access was more difficult than during installation,” Luis says, because installation work on the rest of the detector had blocked easy access. “We had to use a human chain – the first person took the board off and passed it back to the next.”

Luis’ team finished repair work on the End-Cap on Side C in the summer, and worked on the End-Cap on Side A later in the year. They are now finishing off work on the barrel, and they will have finished testing the repairs before the end of March.

During the refurbishment work, Luis’ team fixed another small problem related to the shaping time of the electronic signals which had been identified previously and which, if not corrected, would have made the calibration of the LAr channels more tedious, he says. “So the exercise was profitable and will make our calibration effort simpler .”