ATLAS e-News

23 February 2011

Bringing the vacuum to its lowest value

28 July 2008

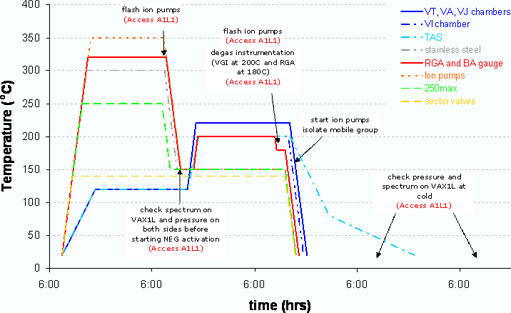

Bake-out cycle for the ATLAS beam vacuum chamber. 3 active days, plus 2 days for assessment, due to start this week.

To minimize beam-gas interactions, the pressure inside the beam pipe should stay at its lowest possible value. To ensure this, the vacuum chambers have to undergo a bake-out process, which consists of heating up the walls of the beam pipe from the outside. One of the vacuum physicists involved in this bake-out process is Adriana Rossi, from CERN’s AT/VAC group. She explained to ATLAS e-news the critical points of this delicate

procedure, which is due to start this week. The pixel detector

needs to be cooled during the bake-out process which is now possible,

since the Inner Detector evaporative cooling system is functioning

again.

The shape and type of materials used to build the ATLAS beam pipe have been carefully chosen to minimize outgassing during operation, but the bake-out is essential: “This is the only way to remove residual gas molecules in the chamber which would otherwise give rise to background,” Adriana explains.

The CERN vacuum team carries out the bake-out process at different temperatures for the various sections of the beam pipe. More than 90% of the internal surface of the ATLAS vacuum chambers is covered with a special material, known as Non-Evaporable-Getter or NEG pump. For the NEG-coated sections, the bake-out will take place at about 220 C. At this temperature, the coating becomes activated and starts trapping gas molecules onto the chamber walls, improving the vacuum.

For the sections that are not coated with the NEG pump, the bakeout temperature will have to go up to 350 C to clean the internal surface from impurities, resulting in a very low outgassing: “The metallic surface of the beam pipe is a sort of sponge in which gas molecules are trapped, as you increase temperature, molecules move faster and come out of the superficial interstitials and the final gas reservoir is much lower,” Adriana explains.

The ATLAS detector bake-out system is unique among the rest of the LHC experiments’ beam pipes, as the ATLAS baking elements are fixed permanently and are not removed during beam operation.

“Normally you want to minimize the amount of material between the place of collision and the detector, which is why the baking elements are usually removed after bake-out for the other experiments, but in ATLAS, these elements are optimized in thickness and mass such as to not interfere with the measurements,” says Adriana.

When ATLAS will be definitely closed, the advantage of having a permanent system will stand out as bake-out cycles will be done with no need to open up the detector to put back and take away bake-out elements, avoiding all the delays that that might involve.

“Having a permanent system helps avoiding several steps, but in the end, it’s a matter of cost and of how much material the sensitivity of the detector can tolerate,” she adds.

During the bake-out process, vacuum scientists face critical issues, such as the need for continuous monitoring of extremely low pressures inside the beam pipe: “If we make a mistake, we risk to provoke a leak in the vacuum chamber. This could bring atmospheric air into the beam pipe and burn-out the NEG pump, because this material becomes very active with air,” Adriana says.

Last week, the final tests started to check the good functioning of all the elements of the bake-out system. Additional tests were also performed to measure the heat load to the detectors. So far, the tests are giving good results and the CERN vacuum team feels confident that everything will go according to plan during the real bake-out process, which will last for three days: “When finished, we expect pressures below 10-9 Pa in the central parts of the beam pipe,” Adriana concludes.

Cristina JimenezATLAS e-News

|