ATLAS e-News

23 February 2011

Liquid Argon: taking the power back

24 March 2009

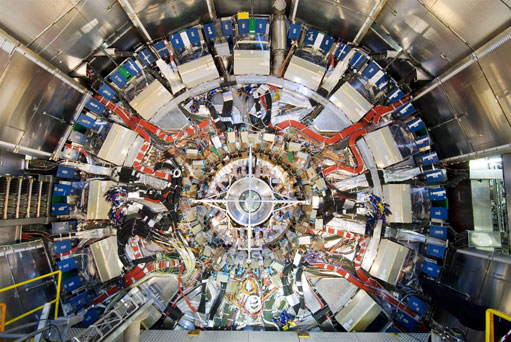

The Liquid Argon barrel, nested between TileCal and the Inner Detector. Power supplies installed behind the green plates near the blue-plated Tile fingers.

The winter shutdown has been a busy time for the folks working on the Liquid Argon Calorimeter. In addition to the routine repair of a handful of noisy or unresponsive read-out channels, they have spent the last five months tackling two major problems – namely: unreliable power supplies and spontaneously failing optical couplers.

The power packs that furnish the front-end electronics have long been a source of frustration due to failures from their original design and construction. Although they were completely refurbished by a new company in 2006, problems inherited from the first vendor still remain.

Luckily, they held out during the operating period last year, but two of the 58 packs went into “redundant mode”. Each pack uses several modules to produce the required current for a given voltage, but if one module fails – in these instances, due to failing capacitors – the other modules take over. Once in this “redundant mode”, the power pack cannot tolerate a further failure in any of the remaining modules if it is to keep up the required voltages.

Things took a turn for the worse when the detector was opened in November last year. LAr engineers discovered that poorly designed and fabricated circuit boards had potentially been causing sparking within the units, and there was nothing else to do but remove the lot and ship them off to the US, to the company who had helped out with the first refurbishment campaign.

“[The power packs] have had a turbulent life, because they weren’t well-built from the beginning,” says LAr Technical Coordinator Luis Hervas. “We’ve had to recover what we had by patching it as best as we could, but we know that it won’t hold for 10 years.”

Anticipating the eventual demise of the power supplies in their current form, the LAr team are gearing themselves up to replace all 58 at some point. Two companies are currently building prototypes, with the 2010 shutdown chalked in as the change-over date.

More worrisome right now is the unexplained and seemingly random failure of some of the optical transmitters that send data from the front-end boards. Last year, in groups of two or three, a total of eight out of 1500 of these transmitters failed over a period of several months, leaving little holes in the “picture” of the calorimeter.

The reason why they failed in groups is a mystery, although the problem has been pin-pointed to the optical element of the transmitter. A working taskforce involving specialist companies and labs has been commissioned to try and discover the root cause, while new designs for replacement transmitters are being pursued in parallel – just in case.

“We have a prototype ready, but since we don’t know why the transmitters failed, we don’t know if we’re making the same mistake again,” explains Luis, who cites corrosion due to humid surroundings, or electrostatic discharge at the time of construction as potential culprits for the failures. “We’re also trying to estimate what percentage [of the original design] will fail – if this is a five per cent problem or a 90 per cent problem – by looking at spares we have.”

For now, this is a medium term issue. Investigations will continue well after the detector has been closed up again, and an informed decision will then be made about whether or not all the optical transmitters need to be replaced. “Let’s call it a ‘pending problem’,” says Luis with a resigned smile. “It will come back to us, but the question is – is it one per month, two, or more?”

In the meanwhile, the heavy job of removing and refitting the power-supplies is now more than half complete. Side A is ready to be closed up again, and the refurbished power packs destined for Side C ought to be received back from the US in the next few weeks. They are scheduled for installation before their final deadline of May 18th.

Ceri PerkinsATLAS e-News

|