ATLAS e-News

23 February 2011

News from the Pit

13 May 2008

This article was corrected on 2 June 2008 to include contributions of IT/CO.

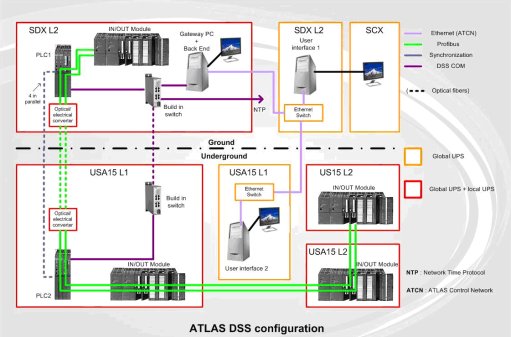

Diagram of the Detector Safety System installed in ATLAS

The detector safety system (DSS) of the ATLAS detector is getting ready for its important function putting the detector in a safe state in case that a potentially dangerous situation arises during operation. Fernando Pedrosa, the engineer responsible for the safety system explains to ATLAS e-news its main features and what are the lasts steps towards the completion of it.

The IT/CO group, as part of the JCOP collaboration, develops the DSS and provides it to ATLAS, as well as to the other LHC experiments, ready to be configured. ATLAS engineers and physicists then can tailor the system to the detector’s specific safety needs by configuring its own sensors and actuators. The ATLAS DSS team also defines the "alarm conditions" on ATLAS in order to link the hazards detected by the sensors with the protective actions taken by the actuators.

The DSS covers level 2 alarms, which protect the detector itself. With this purpose, there are independent sensors connected to the DSS racks to detect safety hazards: “If the sensors detect any anomaly, the alarms will go ON, triggering the actions required to bring the detector into safe state,” Fernando explains.

The majority of the sensors identify changes in the surrounding of the detector and in the services that allow its operation, such as availability of cooling, presence of smoke or flammable gas in the air, etc. A typical example of an action triggered by an alarm is to cut the high and the low voltage systems in case of a cooling failure.

The alarms can also be coupled to the sending of SMS or e-mail messages, but in any case, there is no need for an operator to take any action: “After the problem is understood and sorted out, the operator (SLIMOS) can acknowledge the DSS actions and only then the equipment can be switched ON again,” Fernando says.

The DSS was firstly installed in the USA15 in July 2005. Back then, the ATLAS DSS was protecting parts of the detector under construction. In 2006, the DSS became one of the firsts pieces of electronics installed in the ATLAS SDX1 counting rooms. Ever since then, the DSS has been gradually configured to cover safety aspects in each of the ATLAS subdetectors.

At the moment, the ATLAS DSS team is finishing the installation of the safety system in the Liquid Argon and Tile calorimeters and they are now concentrating on the definition and implementation of safe state in the Muon system and the Inner Detector: “Because of the high sensitivity of the Inner Detector, more caution needs to be put in the definition of safe state of the different parts of it, in comparison to that of the more resistant sub-systems like the calorimeters,” Fernando says.

While planning the safety system, the ATLAS DSS team has to take into account all the conditions that can damage the sub-system, such as high humidity and consequent condensation, power and cooling failures or fire: “Together with experts from the Inner Detector, we are designing a system that will put the detector in safe state when an alarm arises, but also ensuring that no DSS action will damage the system,” explains Fernando.

The team expects to finish putting together the DSS in all the sub-detectors by middle of June: It will depend on each system’s responses, Fernando says. But I’m confident we are converging to the right place in the right time.